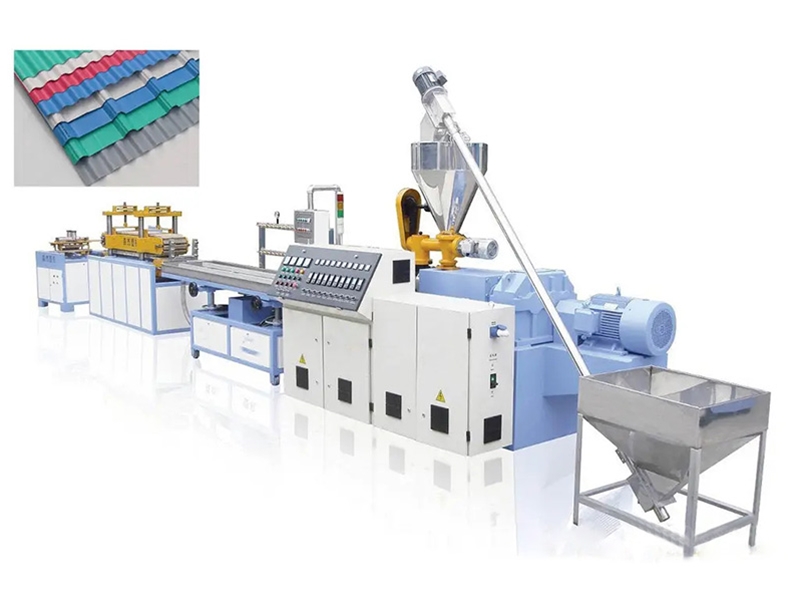

Details

Uses and Features

1. The screw is designed with special mixing function and high plasticizing capacity to ensure plastic melting, uniform color and high extrusion capacity.

2. The hanger-type die head adopts a special double-throttle design, which makes the thickness adjustment of the plate more precise.

3. Temperature control ±1°C can precisely control the plasticizing process and the thickness and flatness of the sheet.

4. The forming roller platform adopts a vertical or 45° inclined arrangement, which can be lifted and lowered freely, which provides more options during the operation of thick and thin plates and improves the quality of the plates.

5. Forming roller circuit cooling system, cooperate with the mold temperature controller to precisely control the temperature of the pressing roller, so that the thickness of the plate is uniform.

6. The slicer cuts the plate length and quantity accurately.

7. Winding table device: It adopts advanced torque motor and cooperates with four-axis automatic tension control, which can adjust the speed and winding tension at will to achieve the purpose of flattening the sheet. With the slitting device, the required product width can be freely set. The machine is equipped with an automatic meter counter to set the product length.